Kunisawa How its made

How Japanese Kunisawa notebooks are made.

Step by Step...

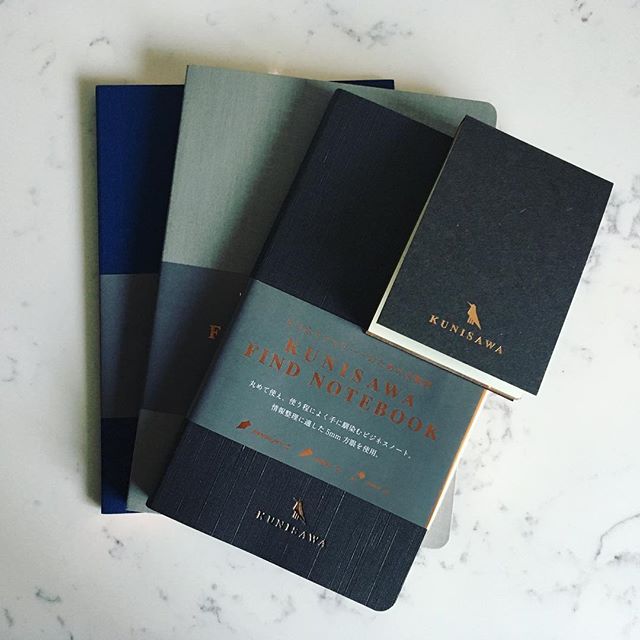

Kunisawa notebooks are THE luxury Japanese stationery item. Being made with the best materials & lots of hand processes, they protect your precious memories and notes. We don’t go anywhere without our Japanese notebook, it keeps our business on track. With the 5mm grid paper inside, its perfect for writing, numbers and drawing. The paper is brilliant for anything you can get your hands on from a calligraphy pen to a pencil. Enjoy the photo gallery below of how these beautiful notebooks are made.

1.It always starts with the covers, whether made of thick textured card or a hard wearing cloth covering, each one is hand stamped with the Kunisawa logo. This is done using a hot foil letter press machine that de-bosses the cover and adds the signature foil at the same time.

The Kunisawa logo is of a Japanese mythical three-legged crow called Yatagarasu やたがらす. The crow used a golden luminance to guide Emperor Jimmu on his journey through the dark roads of Kumano in 660BC, who was a descendant of Sun Gods, as Japanese legend has it.

The three legs of the crow represent Heaven, Earth and Humanity and are all part of the same body.

2.As you would expect, Kunisawa adopts the best quality and most robust method of book binding for the pages inside, the final process is called Case binding.

The pages are folded into sections of multiple pages, before being sewn together down the middle on the same machine they have used for generations. This ensures that the pages are secured together so well, this is essentially a notebook in itself. But to finish the case binding, the notebook gets a final glued cover at the assembly.

3.This is the most exciting stage, where the notebooks get their beautiful metallic bronze foiling. The notebooks are places into a clamp and tapped down to make sure every page is perfectly lined up.

The pages are put into a clamp & sanded before, a thin layer of glue is hand applied to the edges of the pages. They are then passed through the foiling machine, where the sheet of metallic metal is applied to the edge.

Gilt edging the pages of a book goes back centuries and while it is beautiful to look at it has another use.

The thin layer of metal helps stop moisture, dust and any other nasties from getting into your notebook pages. This makes your Kunisawa notebook last much longer than one without gilt edges.

4.The final stage is to assemble and finish off the notebook. The stitched spine is covered in a layer of strong glue and the woven bookmark is put in place.

Then the external cover is added to the glue covered spine. This is always done by hand as it is a precise job to make sure the right amount of glue is added and everything is lined up correctly.

The internal cover page, that has been stamped with a letterpress machine, is finally glued to the front and back pages to finish the notebook.

After drying in a wooden press, to make sure everything is well glued together.

Your beautiful Kunisawa notebook is then ready to be shipped!